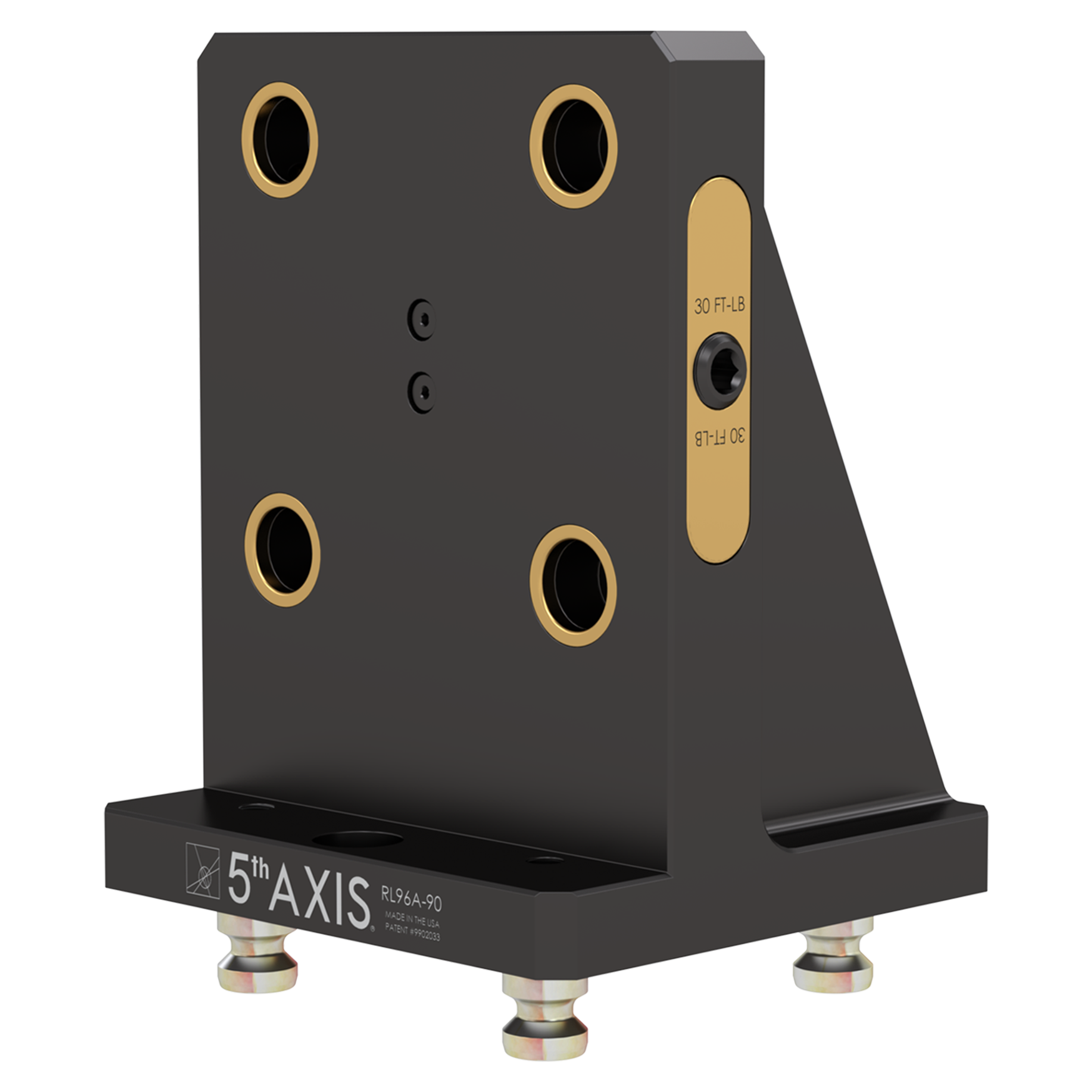

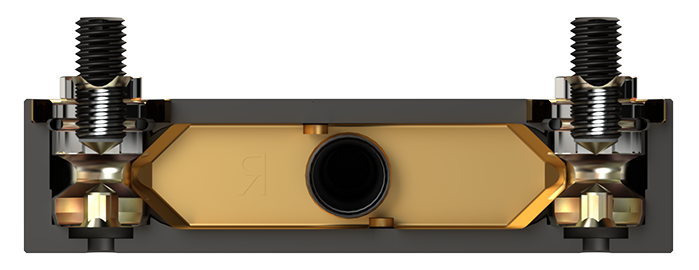

90 Degree Adapter (Multi-Mount)

RL96A-90DEG$1,439.00- Aerospace-Grade Aluminum Construction

- Industry Standard 96mm Pull Stud Spacing

- Adaptable Design for Multi-Side Machining

- 90° Right Angle Plate for Cost-Effective Multi-Side Machining

- Features Pull Studs for Mounting onto Any 96mm RockLock™ Plate

- Includes 2 Counter Bores for Traditional Mounting to Machine T-Slots (4″ or 100mm)

Constructed with aerospace-grade aluminum, the RockLock™ base embodies the perfect blend of versatility and robust durability. Its industry standard 96mm pull stud spacing ensures a seamless fit into your machining setup, reducing unnecessary bulk while maximizing workspace efficiency. One of the standout features of this system is its adaptability. Inside the RockLock™ base, you’ll find hardened steel internals that are engineered for precision and longevity. The 90° right angle RockLock™ plate is the perfect low cost solution for multi-side machining. Machine 5 sides of a part without a 5 axis machine. The unit features pull studs on the bottom so that it can be mounted onto any 96mm RockLock™ plate. It also has 2 counter bores for traditional mounting to machine T-slots at 4″ or 100mm. Simply machine your material, unlock the system, rotate the material, lock the system and continue machining.

| File Name | Size | |

|---|---|---|

| 2D Drawing | 217 KB | Download Now |

| 3D Model | 354 KB | Download Now |

-

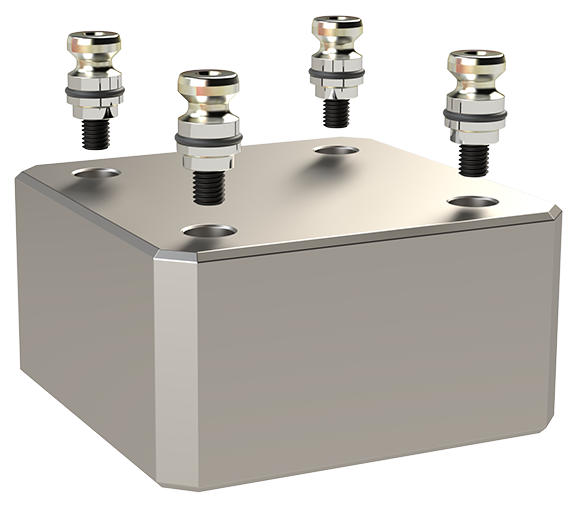

96mm Master Gauging Pallet

96mm Master Gauging Pallet$489.00

-

96mm Pull Stud (Single)

96mm Pull Stud (Single)$31.00

-

-

96mm Pull Stud Set

96mm Pull Stud Set$148.00

In stock

FAQ

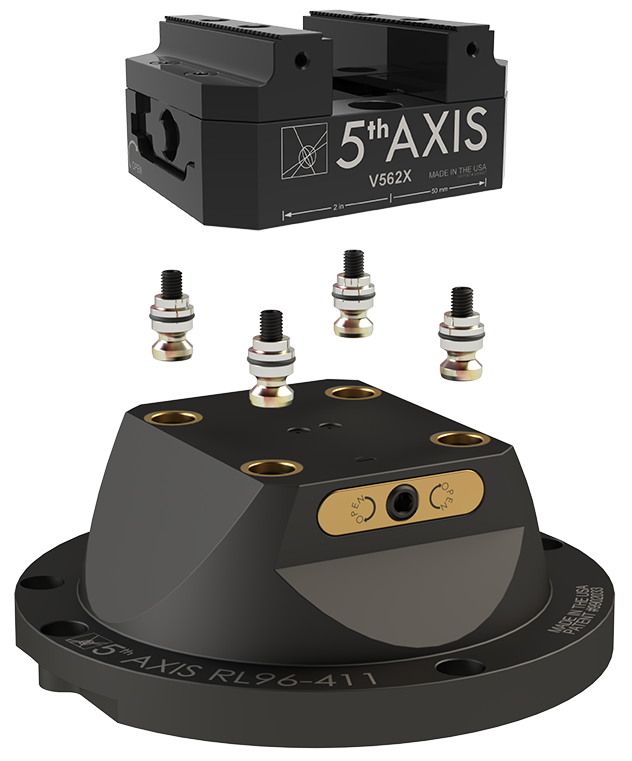

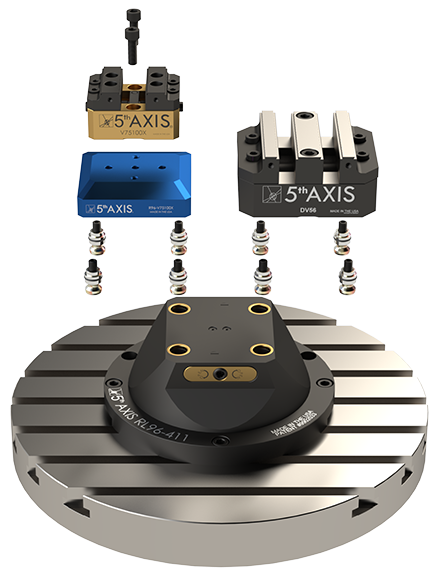

We’ve designed RockLock™ plates in a variety of styles to perfectly fit your CNC machine. Whether you need low-profile plates, multi-position plates, risers, pyramids, tombstones, or right-angle adapters, RockLock™ is available in nearly any configuration you can imagine. Use our 3D machine configuration tool to find the best RockLock™ setup for your machine.

You should expect a pull-down force of 2000lb preload at each pull stud. There are four pull studs in every RockLock™ quick-change system.

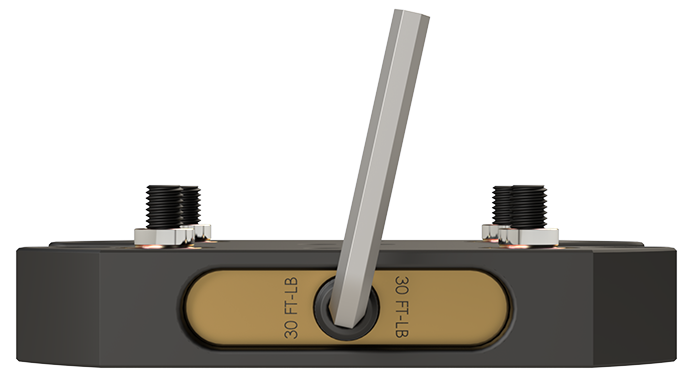

When the leadscrew is tightened using an Allen wrench, the clamping pull studs are pulled down by two free float cam pieces. The precision OD on the pull stud is located on the precision ID of the RockLock™ plate and the cam pieces locks the pull stud into position.

Yes, the RockLock™ quick-change system uses the industry standard 52mm or 96mm pull stud spacing. This allows interchangeability between competitive systems. Each manufacturer has a different patent on the cam system and how it interacts with the pull stud. This means that the base plate and the pull stud must be from the same manufacturer, but the vises and top tooling are completely interchangeable.

Ensure your RockLock™ base (RL96 or RL52) is securely mounted to your machine table or tombstone.

Engage the pull studs into the RockLock™ system by actuating the clamping mechanism (typically via a torque wrench).

Utilize a dial indicator or probe to touch off on the top and sides of the master pallet. Use the clearance holes to loosen or tight the masterpallet and continue to adjust until the master pallet is in alignment with your machine.

We do not put a specific weight limit on the system. Here are so considerations when looking at the weight of your workpiece:

Clamping Force & Holding Torque – Systems like RockLock™ use pull studs and clamping mechanisms rated for specific loads. The 96mm system, for example, is designed to handle significant forces and is suitable for heavy-duty applications.

Workpiece & Fixture Weight – While the RockLock™ system can handle hundreds of pounds, the machine table’s load capacity often becomes the limiting factor.

Dynamic vs. Static Loads – While a system may hold a heavy static load, high-speed machining and cutting forces introduce dynamic loads that can impact stability.

Machine Table Limitations – The weight of the fixture + workpiece should not exceed the machine’s table weight rating.

Yes, the RockLock™ system was built to be open source and compatible with existing subplates and fixturing. We know fixturing and tooling is expensive and we designed the system to make existing subplates and fixtures adaptable to the RockLock™ system. We will provide you with the drawings to easily prep your fixtures to work with the RockLock™ system.

No replacement parts available.

You May Also Like

- $1,439.00

- $1,369.00

- $729.00

No Comments yet!