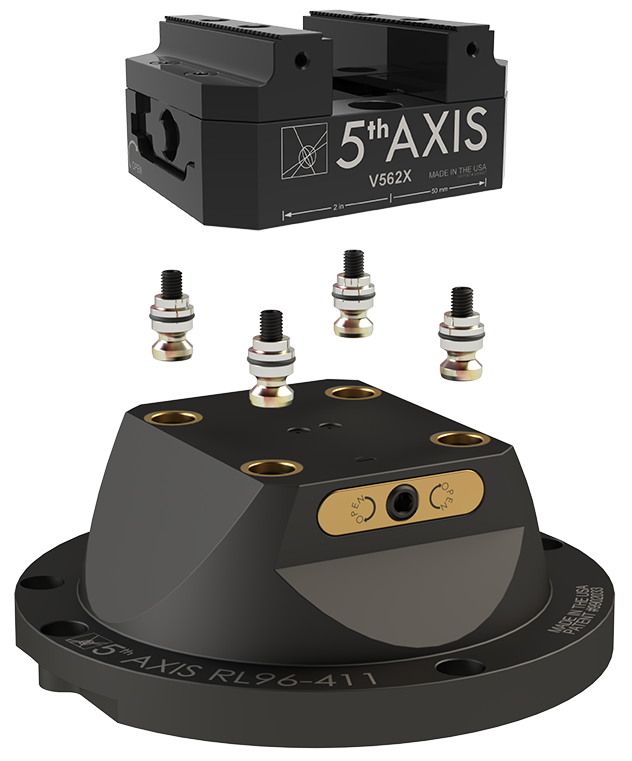

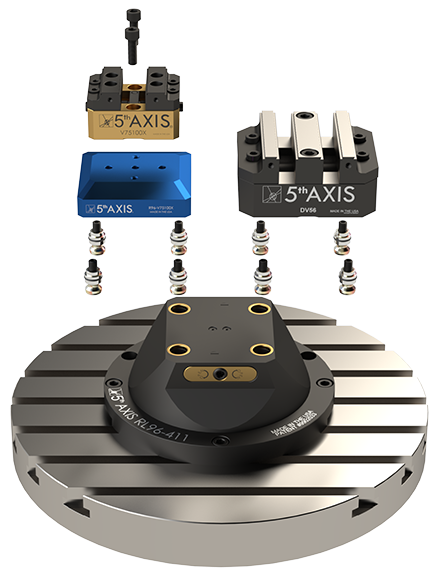

DM25 4 Position Dovetail Top Tooling (96mm)

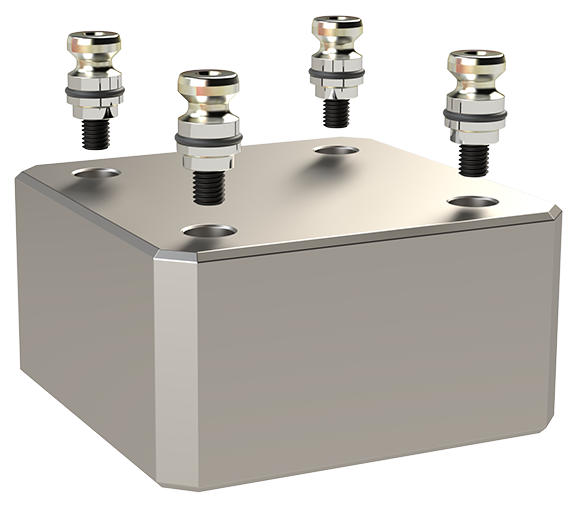

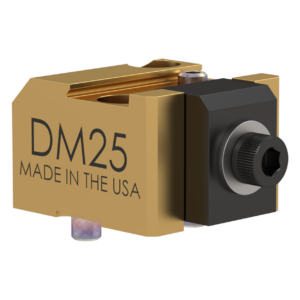

R96-P4DM25$1,955.00- Compact pyramid with 4 DM25 dovetail fixtures.

- Simultaneously machine four parts for efficiency.

- Versatile fixture for trunnions, pallets, and machine tables.

- Trust in quality, precision, and innovation.

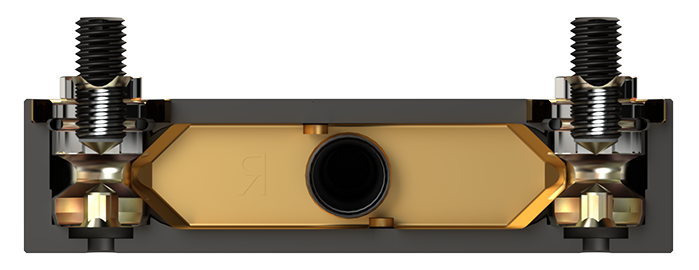

Invest in the future of machining with our 5th Axis RockLock™ 96mm Quick Change Top Tooling System. Stay competitive, boost your productivity, and achieve exceptional results in your machining operations. Trust in our commitment to quality, precision, and innovation, and take your machining capabilities to new heights today. This compact pyramid utilizes 4 DM25 dovetail fixtures. The small footprint ensures no space is wasted allowing simultaneous machining of four parts. Run more parts per cycle and minimize pallet and tool changes. This versatile fixture can be mounted on trunnions, pallets, and machine tables using our 96mm RockLock™ Quick Change System.

| File Name | Size | |

|---|---|---|

| 2D Drawing | 110 KB | Download Now |

| 3D Model | 196 KB | Download Now |

| Dovetail Stock Prep & Troubleshooting Guide | 1 MB | Download Now |

Only 1 left in stock (can be backordered)

FAQ

Consider your part size, machine table space, and automation needs. Use single-station vises for flexibility or double-station vises to maximize density.

No, 96mm top tooling is only compatible with 96mm RockLock™ bases. For 52mm systems, use the corresponding 52mm top tooling options.

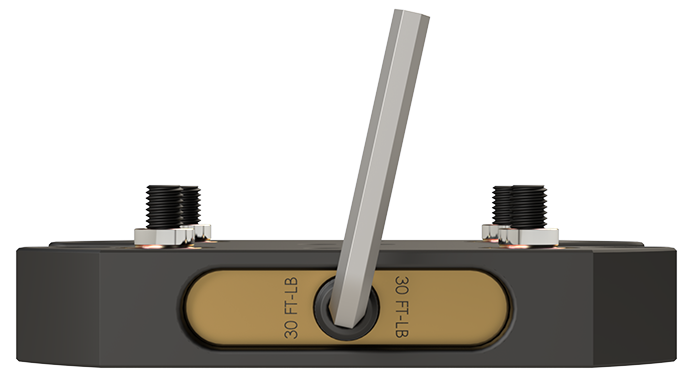

The 96mm RockLock™ system provides ±0.005mm (±0.0002″) repeatability for high-precision applications.

The pull studs and the quick-change base must be from the same manufacturer, but the top tooling is interchangeable. The 96mm spacing, counter bore and thread size are common between competitive systems.

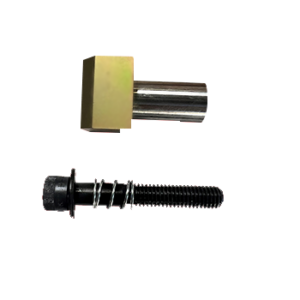

Replacement Parts

- $78.75

You May Also Like

- $440.00

- $440.00

No Comments yet!